Have you ever faced construction delays?

Over 90% of major projects run overtime and over-budget.1

It’s true; we are all too familiar with projects running behind schedule. The dreaded delays directly affect revenue and increase overheads.

And you likely know the usual culprits–labor problems, weather delays, sociopolitical factors, and coordination errors. But there’s no point mulling over the problems.

So, let’s be solution-focused instead. How can we ensure that a project completes within the stipulated time-frame? These solutions initially come to mind:

- Better project management right from the project outset

- Work with GCs that have good relationships with subs and the local labor force

- Set realistic expectations

What else?

Let’s Pivot the Perspective

While the above solutions help, the most effective ones may not be so obvious. Let’s skim through a few of them:

- Get every detail–down to nails and fasteners–finalized from the design stage, before the foundation is ever laid out

- Pre-planning saves material waste and helps facilitate demand and supply out-front

- Reimagine operations: Find optimum iterations, material, and labor strength to achieve the maximum efficiency possible

- Automate repetitive processes

- Move construction to a weather-proof space (controlled environment)

Before you dismiss these for not being practical or easy enough, let me tell you that these solutions not only exist but also give resounding results.

Enter DfMA

It all starts with and revolves around an extremely streamlined design practice: design for manufacture and assembly.

When you already know every little thing to be used in your project, have your supply chain simplified and streamlined, and have all project stakeholders know exactly what’s happening at any point of time–your schedule projections become way more accurate and your timeline, compact.

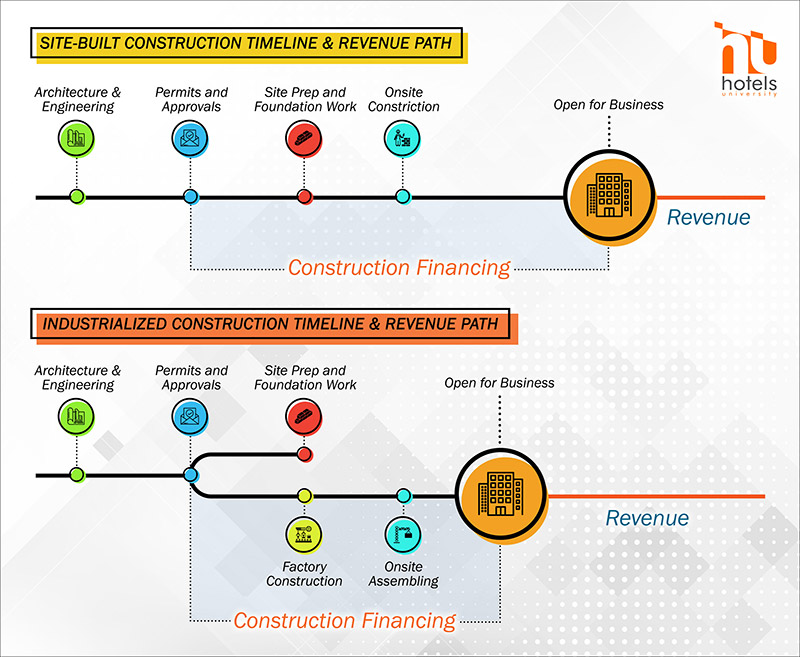

You have most likely heard of modular construction and prefabrication. These modern techniques put construction on the assembly line in a manufacturing plant, away from the jobsite. McKinsey & Company reported 20-50% acceleration in timelines for modular construction projects.2

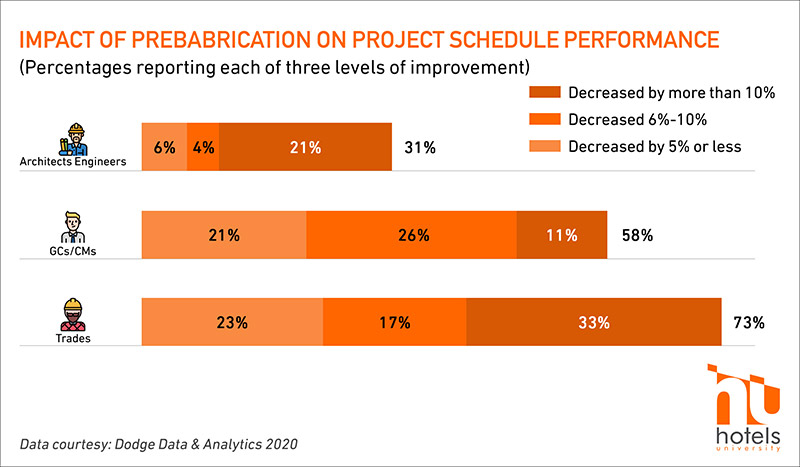

Prefabrication–also known as industrialized construction–involves all forms of manufacturing of construction, including modular. Here’s how the industry observed its impact on project schedules:

The point is, this is all happening around the world and it’s the future of construction.

Making the Move

I know that the thought of taking a new avenue feels overwhelming. Venturing into the unknown can be uncomfortable–but also rewarding.

That’s why I’m stepping up to the challenge of providing the guidance needed for you to explore industrialized construction. You don’t have to go all-in at once, for industrialized construction caters to a range of products–from prefabricated flooring, roofing, and panels to fully furnished modular rooms and bathrooms.

We at BASE4 have mastered the art and science of industrialized architecture–or DfMA. But more importantly, we realize the need for education. We aim to educate our industry for us to collectively reach the maximum potential and keep building better.

If you’re looking for ways to rethink construction, I invite you to reach out with your ideas and questions. Happy to resolve any queries you may have.

Let’s build better!

Thank you,

Blair Hildahl

Blair@hotelsuniversity.com

608.304.5228

Sources:

1 https://www.mckinsey.com/industries/capital-projects-and-infrastructure/how-we-help-clients/mckinsey-major-project-delivery/distressed-project-turnaround

2 Modular construction: From projects to products – McKinsey & Company; June 2019

Leave A Comment